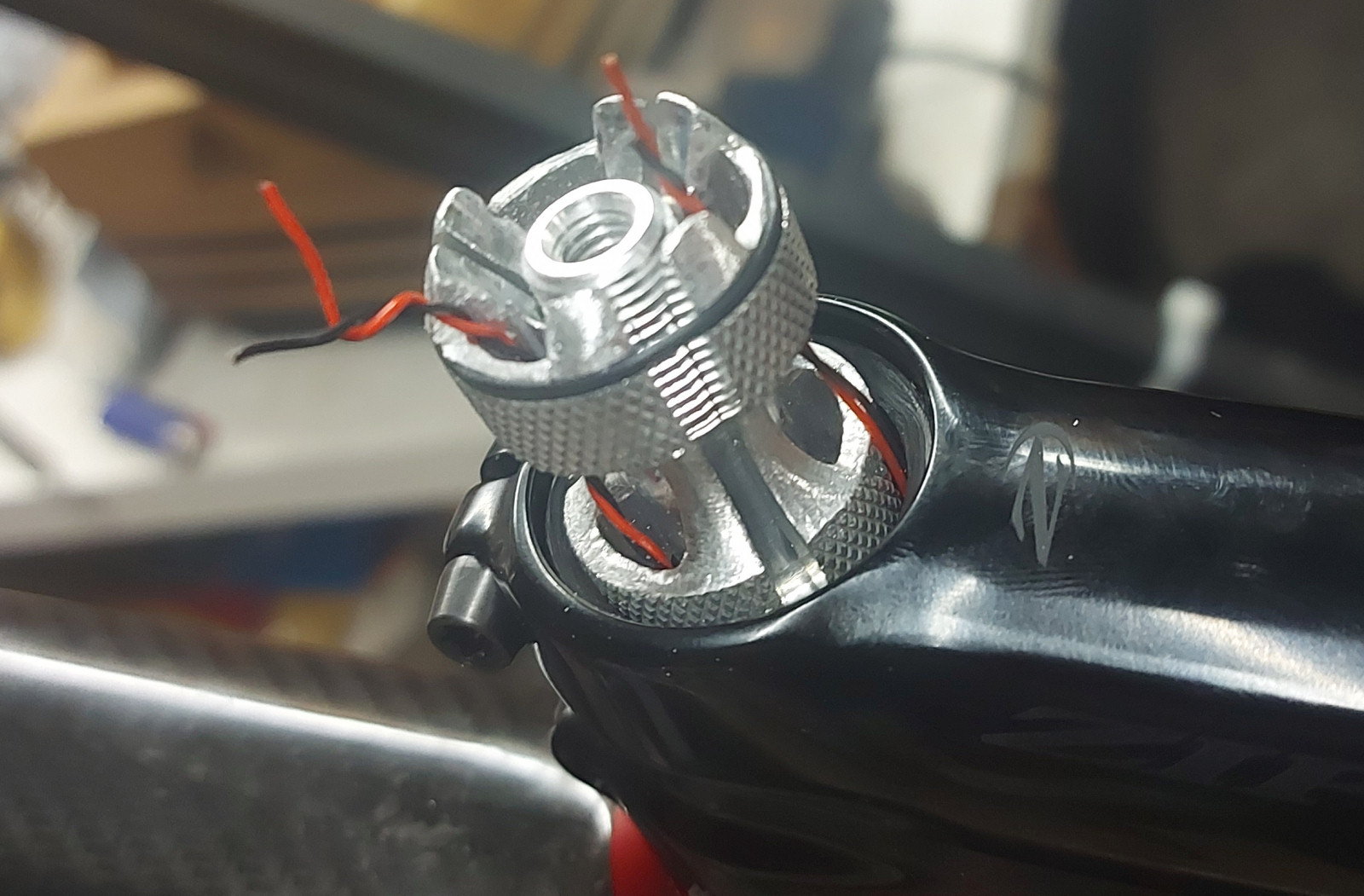

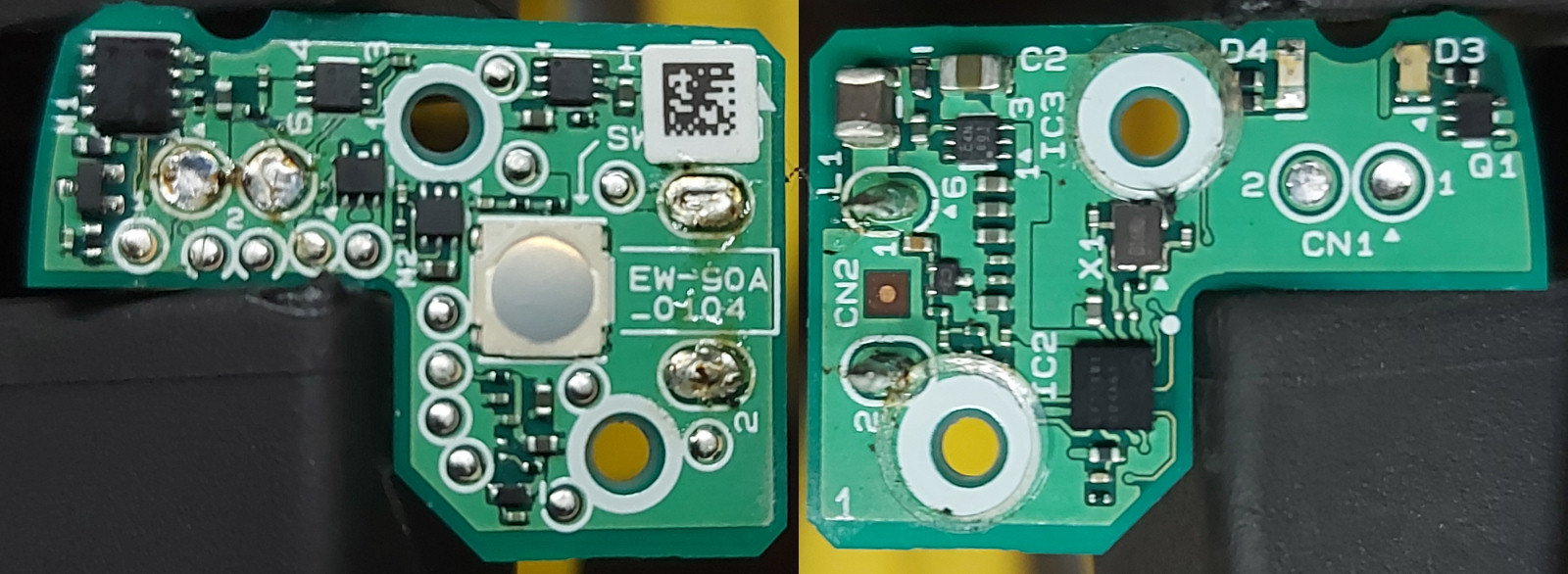

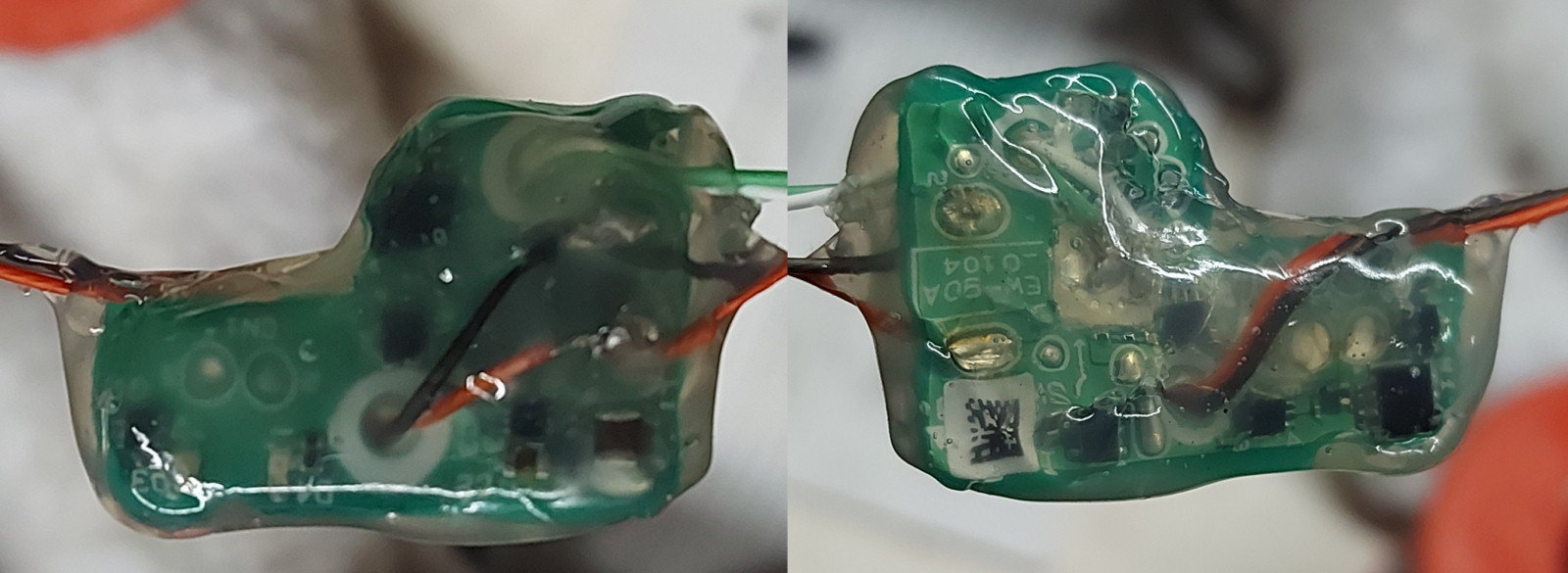

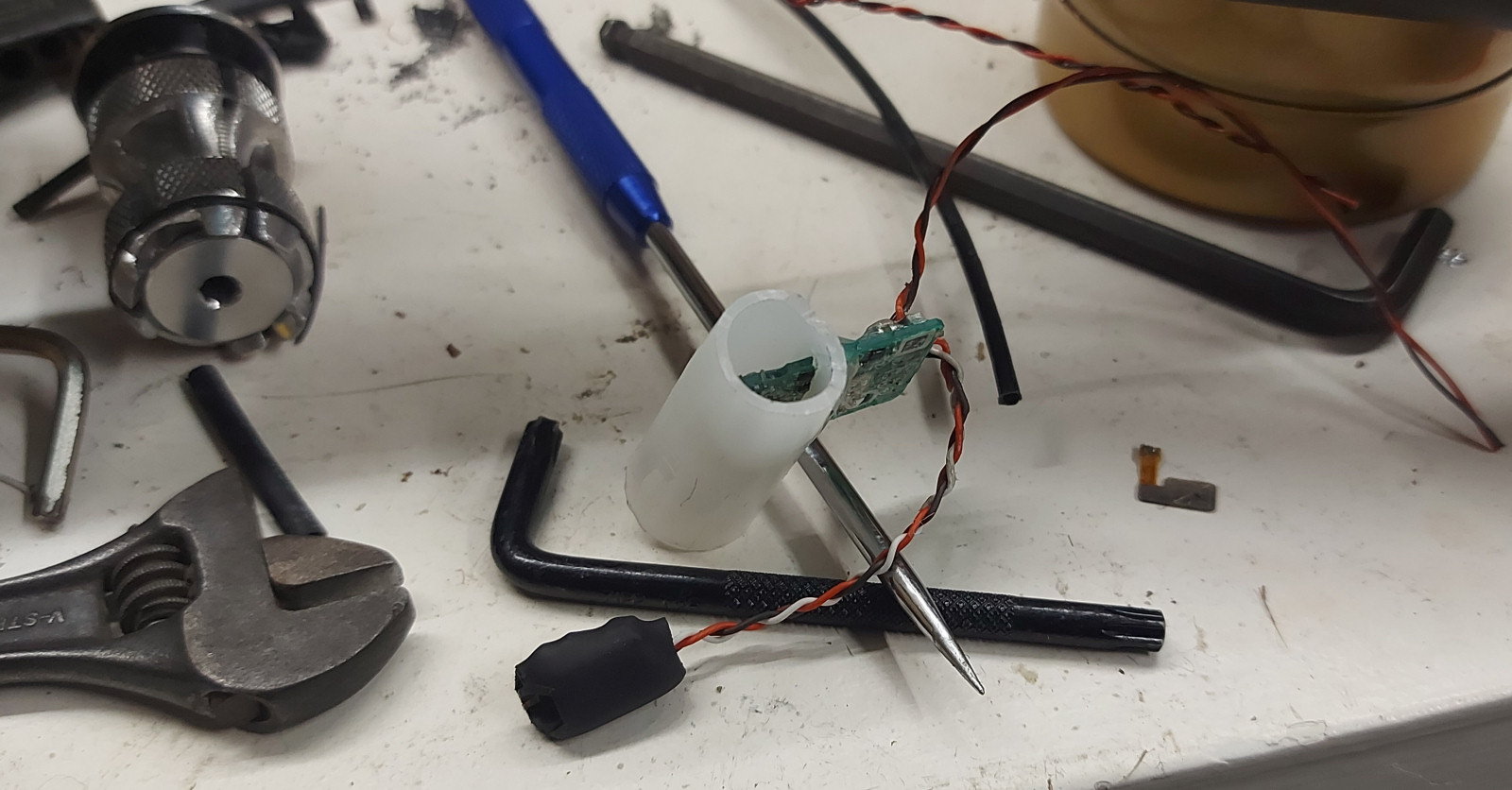

The SM-EW90-A is now just a tiny PCB inside the stem, hotglued into a section of sealant gun nozzle, which locates it and also serves as a light pipe to a small hole in the top of the stem, plugged with hotglue - it looks just like a 2.5mm LED! Sweet. There's a headphone jack from a phone for the ground and signal, plus the junction A button (just contacts ground, so only three wires needed), which is moved up just behind the right shifter. It's a pretty trick retromod if I do say so myself... had to make a couple of 1.8mm holes in the carbon steerer, a 2mm hole in the bars (in the lower part of the section looking into the stem, fingers crossed those fibres weren't too important), a 3mm hole behind the FD, and a couple of 3mm holes in the BB shell to the seat tube and chainstay (they could've been smaller, but those drillbits weren't long enough). I reckon I've probably avoided any serious structural compromise.

You might wanna play it at 1.25 or 1.5x... my video production is a bit crap.

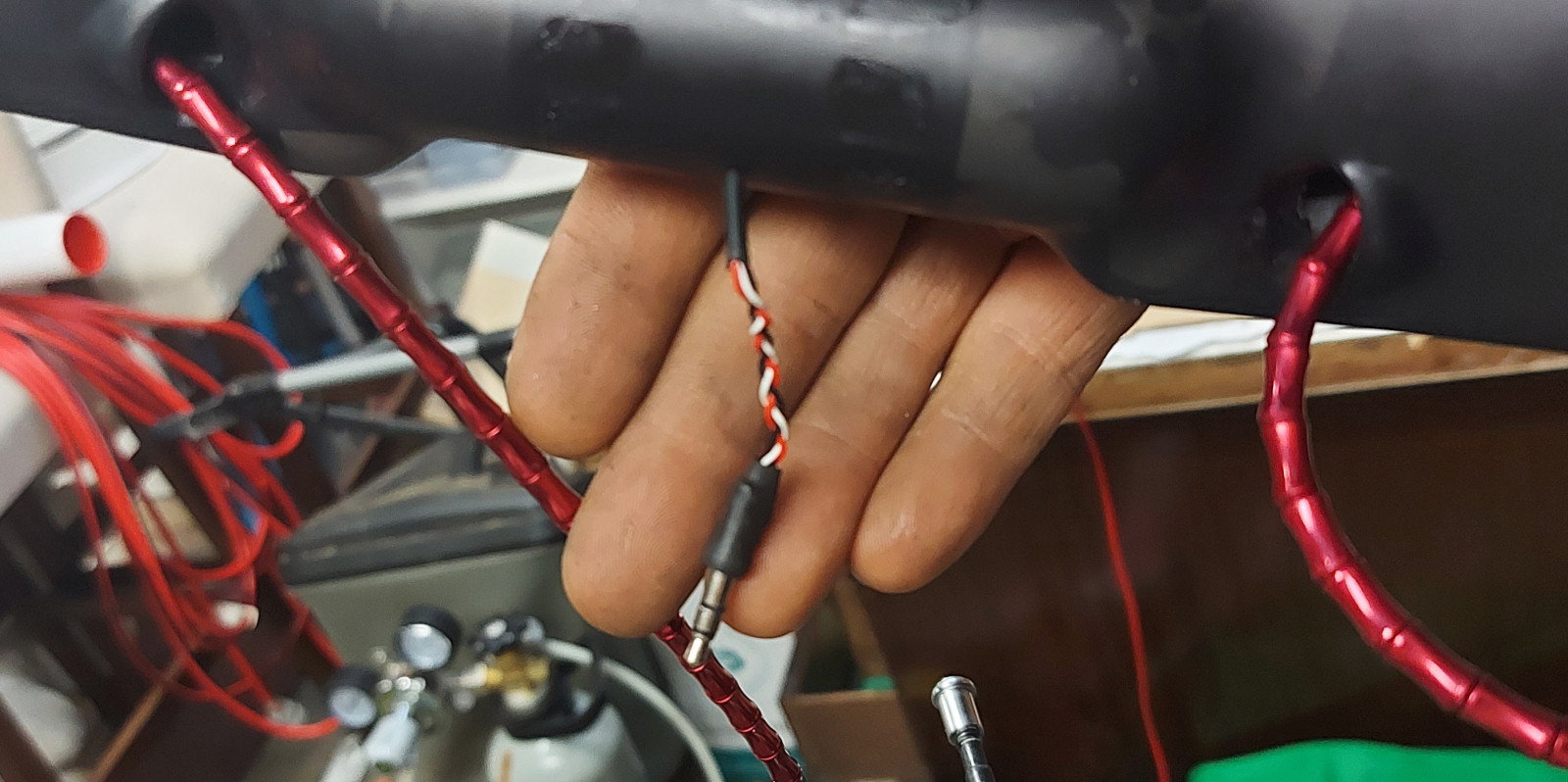

Going the hack on cable guides:

Here's a trick I came up with to stop the file skating off into the paint:

With the dip in the middle, it's a lot easier to hold it square.