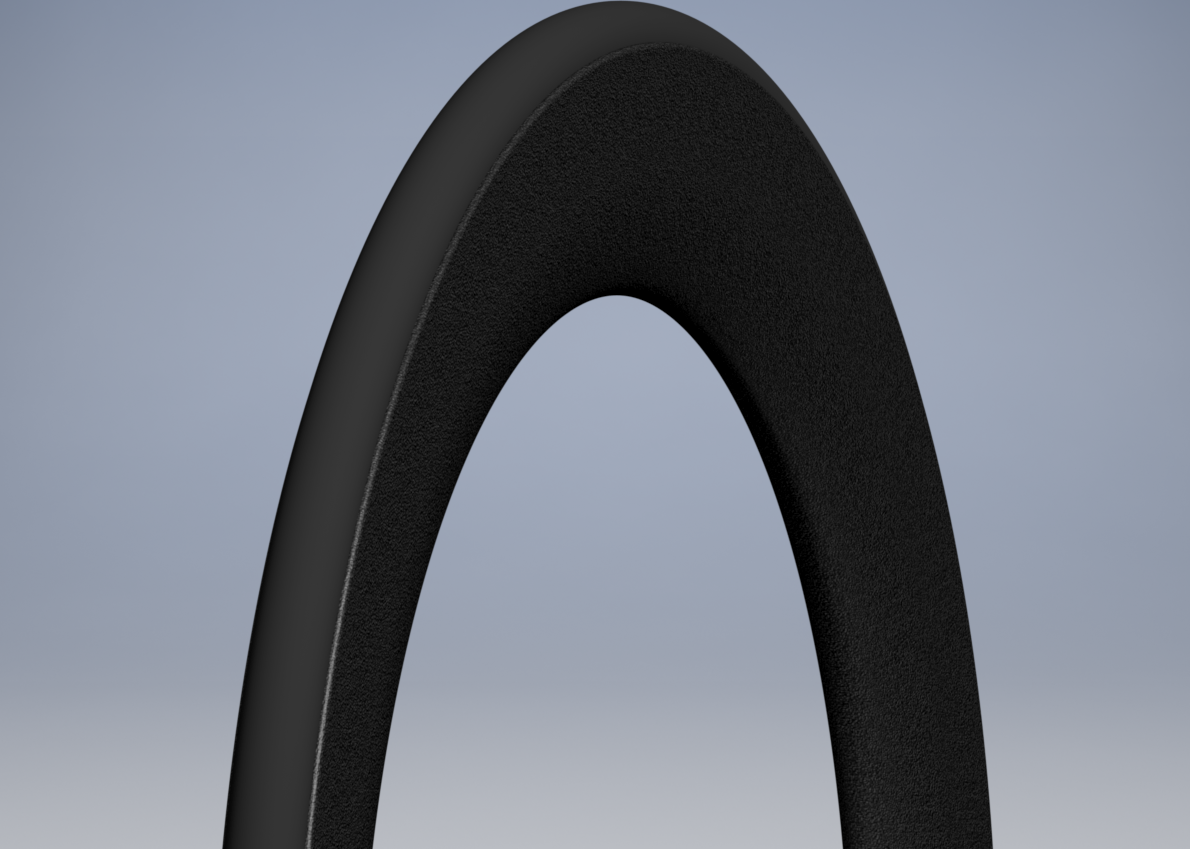

This happened today. Tubeless tire inflated to 120psi left overnight then woke up with this. I haven't use the wheels. Only mounted on the bike. Not my luck maybe

Moderator: robbosmans

Sorry to hear about the issue with the rim. Have to ask why you felt you needed to inflate to 120 psi? For road tubeless, 60-85 psi is generally sufficient to seat a tire, not to mention 80 psi is the max I use out on the road for our Nox Composites tubeless wheels.

Maybe it was your luck that this happened over night at home and not on the road with possible bad consequences.biohazard31 wrote:

This happened today. Tubeless tire inflated to 120psi left overnight then woke up with this. I haven't use the wheels. Only mounted on the bike. Not my luck maybe

Yes it's the other way around. Blessing in disguise1415chris wrote: ↑Fri Apr 20, 2018 7:09 pmMaybe it was your luck that this happened over night at home and not on the road with possible bad consequences.biohazard31 wrote:

This happened today. Tubeless tire inflated to 120psi left overnight then woke up with this. I haven't use the wheels. Only mounted on the bike. Not my luck maybe

120 psi should be within recommended range 90-125 psi, for your 23mm tyres ok.. it was just standing, so it should survive much more to be prepared for ride, braking...biohazard31 wrote: ↑Fri Apr 20, 2018 2:24 pm

This happened today. Tubeless tire inflated to 120psi left overnight then woke up with this. I haven't use the wheels. Only mounted on the bike. Not my luck maybe

What measured width tyre is this being optimised for?

Thanks for sharing your research. This is very interesting! I can see that we will be riding 34mm wide tyres on 36mm wide wheels in a couple of years. Weight might be 100g-200g more than a 25mm tyre and rim, so they will be marginally slower climbing, but faster on flats and descending. They will ride very well on smooth or rough roads, or gravel!vmajor wrote: ↑Fri Apr 27, 2018 6:47 am... I should mention now that when we left the optimiser to run without a rim width constraint the optimal width was 45mm for a 76mm depth.

In essence no current, or likely future bicycle wheel is optimised for aerodynamics because it has to be able to be installed in a bicycle where width and weight are very important considerations. It also means that any claim to the otherwise without specifying the design constraints is pure marketing bull

V.

I thought a rim width of 105% of measured tyre width was ideal for the tyre to wheel transition?