Carbon fiber frame cutaway thread.Internal inside structure

Moderator: robbosmans

I posted this on another Road forum that is half full of comedians and idiots so thought I should post here as well since you guys are more serious.

I was curious as to what the insides of carbon fiber frames look like now and then.

It would be fun to see what old frames look like inside, how uneven the layups were, etc.

I'm particularly curious to see how wall thicknesses vary and how smooth the interior walls are on low end Chinese copycats since my search found nothing.

Obviously most people aren't going to cut up a good frame, but if you crashed yours why not cut it up and show us how the remaining good parts look inside?

Just tell us the year, make, model, and areas you are showing.

Anyone with a bandsaw, or vise and hacksaw can do this easy.

Just make sure you wear a mask and glasses since that dust is not healthy.

It is also interesting to see how the frames are getting smoother/lighter inside as time goes on.

A Google search gave me a good start on the reputable companies that are proud and stand behind their craftsmanship.

Some links have many pics of cutaways and you can see why they charge a premium.

2009 Avanti, ewww.

http://www.cyclingnews.com/features/pho ... pace/12777

2008 Trek Madone fork

http://www.cyclingnews.com/features/pho ... done/12574

2009 Specialized

http://www.bikerumor.com/2009/04/19/spe ... -cutaways/

2009 Time at Eurobike

http://www.cyclingnews.com/features/pho ... rt-5/86697

2010 Focus Izalco Max

http://www.cyclingnews.com/features/pho ... ono/272918

2011 Scott Scale 899

http://www.bikerumor.com/2010/06/25/fir ... new-scale/

2011 Felt

http://www.carbonfiberguru.com/carbon-f ... 2011-line/

2011 Look 695

http://www.bikeradar.com/news/article/l ... iew-26817/

http://www.bikerumor.com/2010/09/30/int ... road-bike/

2012 exogrid tube

http://www.cyclingnews.com/features/pho ... ter/210561

2012 Raleigh RXC

http://www.bikerumor.com/2011/08/02/201 ... tion-more/

2012 Rock Racing

http://www.cebucycling.com/index.php?topic=17430.0

2012 Santa Cruz Blur

http://www.bikerumor.com/2011/04/08/tec ... tr-carbon/

2013 Diamondback Podium

http://www.cyclingnews.com/features/pho ... kes/233066

http://www.cyclingnews.com/features/pho ... kes/233067

2013 Look 695 Aerolight

http://www.cyclingnews.com/features/pho ... ll-details

I was curious as to what the insides of carbon fiber frames look like now and then.

It would be fun to see what old frames look like inside, how uneven the layups were, etc.

I'm particularly curious to see how wall thicknesses vary and how smooth the interior walls are on low end Chinese copycats since my search found nothing.

Obviously most people aren't going to cut up a good frame, but if you crashed yours why not cut it up and show us how the remaining good parts look inside?

Just tell us the year, make, model, and areas you are showing.

Anyone with a bandsaw, or vise and hacksaw can do this easy.

Just make sure you wear a mask and glasses since that dust is not healthy.

It is also interesting to see how the frames are getting smoother/lighter inside as time goes on.

A Google search gave me a good start on the reputable companies that are proud and stand behind their craftsmanship.

Some links have many pics of cutaways and you can see why they charge a premium.

2009 Avanti, ewww.

http://www.cyclingnews.com/features/pho ... pace/12777

2008 Trek Madone fork

http://www.cyclingnews.com/features/pho ... done/12574

2009 Specialized

http://www.bikerumor.com/2009/04/19/spe ... -cutaways/

2009 Time at Eurobike

http://www.cyclingnews.com/features/pho ... rt-5/86697

2010 Focus Izalco Max

http://www.cyclingnews.com/features/pho ... ono/272918

2011 Scott Scale 899

http://www.bikerumor.com/2010/06/25/fir ... new-scale/

2011 Felt

http://www.carbonfiberguru.com/carbon-f ... 2011-line/

2011 Look 695

http://www.bikeradar.com/news/article/l ... iew-26817/

http://www.bikerumor.com/2010/09/30/int ... road-bike/

2012 exogrid tube

http://www.cyclingnews.com/features/pho ... ter/210561

2012 Raleigh RXC

http://www.bikerumor.com/2011/08/02/201 ... tion-more/

2012 Rock Racing

http://www.cebucycling.com/index.php?topic=17430.0

2012 Santa Cruz Blur

http://www.bikerumor.com/2011/04/08/tec ... tr-carbon/

2013 Diamondback Podium

http://www.cyclingnews.com/features/pho ... kes/233066

http://www.cyclingnews.com/features/pho ... kes/233067

2013 Look 695 Aerolight

http://www.cyclingnews.com/features/pho ... ll-details

Visit starbike.com Online Retailer for HighEnd cycling components

Great Prices ✓ Broad Selection ✓ Worldwide Delivery ✓

www.starbike.com

What does this have to do with performance of the bike? I've seen steel bikes with rust on the inside yet they performed and rode extremely well. I've also seen aluminum bikes with extremely ugly welds, like they were done by some Asian sweat shop yet the bike's performance was stellar. If companies implemented a finishing process for inside the frame it would no doubt drive the cost up. Buy why should they do this? Most people that buy bikes care somewhat about what the outside looks like, but don't care about the inside since its not visible and means nothing to the products performance or specs.

Maybe those "idiots" on the other bike forum are more bike riders than idiots.

Maybe those "idiots" on the other bike forum are more bike riders than idiots.

Maybe it doesn't affect performance, but I'm still curious to see the inside of things.

Clearly you are not interested, but why hate on curiousity?

My first 2 links look rough inside, but the 2013 links are pretty smooth and refined inside.

I suspect the smooth even formation of carbon in the latter frames is providing smoother and more consistent flex.

The costs are already up, the 2013 Look 695 Aerolight is not cheap to me.

Yet it has very smooth inner surfaces and claims to ride well.

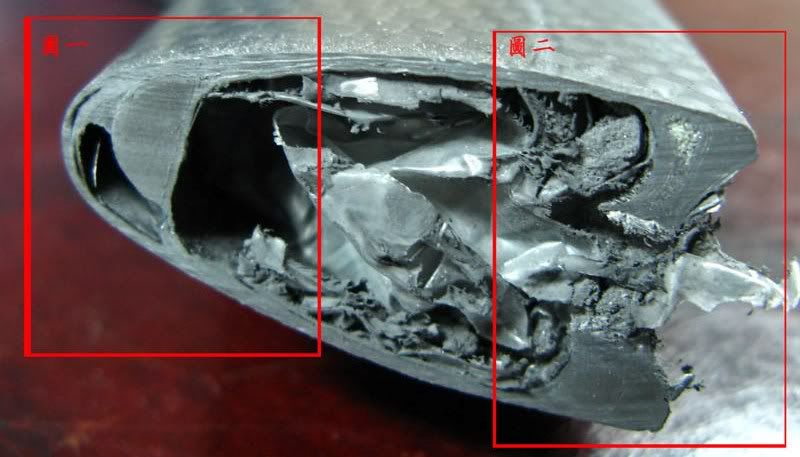

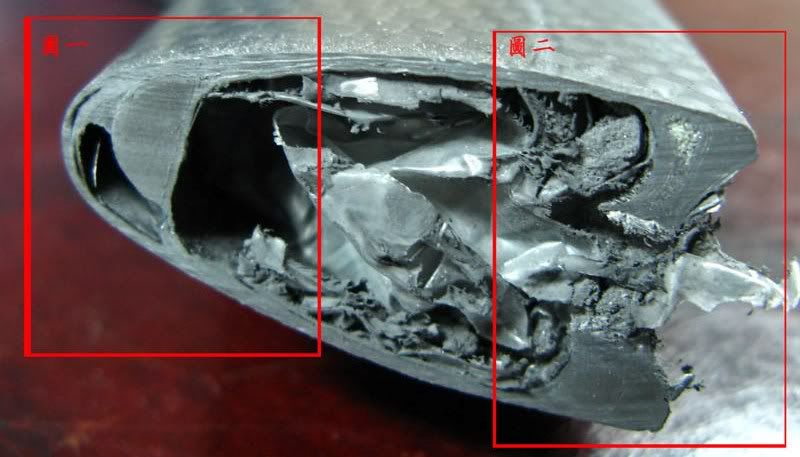

I hate to bring up this common pic again, but I want to know if those knock off Chinese carbon frames look like today's high end bikes inside or more like this old picture inside.

Air pockets definitely affect the flex consistency in CF and if the pocket is big enough the CF might break.

So some cutaways might show air pockets in certain frames.

I suspect the knock offs are actually smooth inside, just thicker walled due to cheaper/thicker carbon weaves.

Without real pics, we really don't know, hence the thread.

These wheels look nice on the outside, but are you still going to say they perform as well as Mavics or Zipps which happen to be smooth and even inside?

I'll admit I'm not a composites engineer, I am an armchair engineer so this is just my deductive reasoning.

Carbon bikes ride better as each new model comes out and their insides are getting smoother and sometimes thinner walled.

Clearly you are not interested, but why hate on curiousity?

My first 2 links look rough inside, but the 2013 links are pretty smooth and refined inside.

I suspect the smooth even formation of carbon in the latter frames is providing smoother and more consistent flex.

The costs are already up, the 2013 Look 695 Aerolight is not cheap to me.

Yet it has very smooth inner surfaces and claims to ride well.

I hate to bring up this common pic again, but I want to know if those knock off Chinese carbon frames look like today's high end bikes inside or more like this old picture inside.

Air pockets definitely affect the flex consistency in CF and if the pocket is big enough the CF might break.

So some cutaways might show air pockets in certain frames.

I suspect the knock offs are actually smooth inside, just thicker walled due to cheaper/thicker carbon weaves.

Without real pics, we really don't know, hence the thread.

These wheels look nice on the outside, but are you still going to say they perform as well as Mavics or Zipps which happen to be smooth and even inside?

I'll admit I'm not a composites engineer, I am an armchair engineer so this is just my deductive reasoning.

Carbon bikes ride better as each new model comes out and their insides are getting smoother and sometimes thinner walled.

Interesting thread, forget the idiots too many threads on the net ruined by comedians etc. You would generally expect the higher the price the better the materials/workmanship. Unfortunately, I am not in a position to take a hacksaw to my Viner just yet.

-

boolinwall

- Posts: 195

- Joined: Thu Aug 23, 2012 11:19 pm

Maybe people can explain to me why they think the inside of a frame doesn't effect the quality? Maybe look up the term "stress riser" and then get back to me. The inside is just as important as the outside in terms of overall strength and ride quality. Most companies have it figured out by now. Some have not. A smooth outside, some paint and polish, and then sponsor some pros. If you do all that, your bike has to be as good as everyone elses,,, right? I personally like this thread. But be careful not to confuse the real manufacturers with the black market knockoffs. Then the thread becomes counter productive.

This is an interesting topic. Fibre composites are designed to spread stress along the strands of material, therefore, surface finish isn't always as important as other materials such as metals; where stress concentrations can cause weak points. Think of Papier-mâché as a crude example of very simplified composite lay up, if the finish is rough, the material properties don't change as much as if the material were made from plastic, or rubber, whereby a rough edge would create an uneven thickness, creating weak points.

The different stress and strain management properties of metals and composites are reflected in frame design; Carbon frames are generally made with more bulky, bulbous, flowing shapes. This is due to the directional force loading the material is designed for. You couldn't build a carbon frame in the same way as a traditional Steel/Aluminium tubed one and expect the same performance/properties.

The level of finish quality required depends strongly on the application. It isn't always necessary to spend the time and money on the internals, however due to advancements in the material and production techniques has allowed for this to be easier.

PLEASE NOTE: This post is only talking about surface finish, rather than the poor manufacture (I presume an air bubble) as shown in the top of the rim section above.

The different stress and strain management properties of metals and composites are reflected in frame design; Carbon frames are generally made with more bulky, bulbous, flowing shapes. This is due to the directional force loading the material is designed for. You couldn't build a carbon frame in the same way as a traditional Steel/Aluminium tubed one and expect the same performance/properties.

The level of finish quality required depends strongly on the application. It isn't always necessary to spend the time and money on the internals, however due to advancements in the material and production techniques has allowed for this to be easier.

PLEASE NOTE: This post is only talking about surface finish, rather than the poor manufacture (I presume an air bubble) as shown in the top of the rim section above.

-

whodesigns

- in the industry

- Posts: 162

- Joined: Thu Jan 08, 2009 12:16 pm

- Location: Melbourne Australia

- Contact:

ttakata73 wrote:I posted this on another Road forum that is half full of comedians and idiots so thought I should post here as well since you guys are more serious.

I was curious as to what the insides of carbon fiber frames look like now and then.

It would be fun to see what old frames look like inside, how uneven the layups were, etc.

I'm particularly curious to see how wall thicknesses vary and how smooth the interior walls are on low end Chinese copycats since my search found nothing.

Obviously most people aren't going to cut up a good frame, but if you crashed yours why not cut it up and show us how the remaining good parts look inside?

Just tell us the year, make, model, and areas you are showing.

Anyone with a bandsaw, or vise and hacksaw can do this easy.

Just make sure you wear a mask and glasses since that dust is not healthy.

It is also interesting to see how the frames are getting smoother/lighter inside as time goes on.

A Google search gave me a good start on the reputable companies that are proud and stand behind their craftsmanship.

Some links have many pics of cutaways and you can see why they charge a premium.

As part of our carbon bike consulting and repair business, this is something we do all the time.

Follow the link to see some examples here http://carbonbikerepair.com.au/index.ph ... &Itemid=13.

We have many more, including some of the latest frames, we just haven't created a document on them as yet.

We are a totally independent company.

As for the structural implications, variations on the inner face are caused by changes in the fiber compaction and resin content as well as the "straightness" of the fiber. These can have significant effects structurally.

Specialist Sports Technology

http://www.luescherteknik.com.au

Carbon Bike Repairs

http://www.carbonbikerepair.com.au

http://www.luescherteknik.com.au

Carbon Bike Repairs

http://www.carbonbikerepair.com.au

Wow, "whodesigns" your link is exactly what I was hoping to see.

Real pics of real frames people buy, very impressive work.

The cuts are so clean, do you guys use angle grinders and fiber cutoff wheels or some sort of metal bladed saw?

Thanks!, I hope you continue to contribute as the newer frames come in.

First, I'm amazed how thin the walls look.

They all look well under 1mm thick, maybe under 0.5mm in areas?

My FSA K-Force MTB bar is several times thicker in comparison.

Now I won't worry since it is probably overbuilt even with low grade carbon.

I was thinking these high end bikes would be more like the show bikes, but as some said before, those were probably prepared just for shows.

The Storck, Time, and Orbea look pretty clean (maybe uses a reuseable rubber bladder when molding?).

I'm guessing the other non-lugged frames use a disposable plastic bag which leaves the wavy resin marks.

Clearly all these bikes are known to ride well enough to command a high price but they all look sloppier than the show bike links for sure.

Maybe because they are older frames?

It is nice to see the variations in joining tubes, internal cabling (Focus Izalco), and how big the metal inserts are.

I don't know if people can sense the difference in ride quality based on interior finish but I think smoother finishing might mean lighter weight.

The old size 58 Cannondale Six is stated to be 1288g (is the fork is part of this weight?). Look how sloppy it is, there's lots of extra resin built up in waves.

The latest Supersix Evo HiMod is so much lighter than this.

I wonder how much weight is saved by having less resin, or adding nanotube resin, or using newer carbon weaves?

If these are what brand name frames look inside; do those Chinese knock offs really look more like the disaster of a photo in the first post?

Real pics of real frames people buy, very impressive work.

The cuts are so clean, do you guys use angle grinders and fiber cutoff wheels or some sort of metal bladed saw?

Thanks!, I hope you continue to contribute as the newer frames come in.

First, I'm amazed how thin the walls look.

They all look well under 1mm thick, maybe under 0.5mm in areas?

My FSA K-Force MTB bar is several times thicker in comparison.

Now I won't worry since it is probably overbuilt even with low grade carbon.

I was thinking these high end bikes would be more like the show bikes, but as some said before, those were probably prepared just for shows.

The Storck, Time, and Orbea look pretty clean (maybe uses a reuseable rubber bladder when molding?).

I'm guessing the other non-lugged frames use a disposable plastic bag which leaves the wavy resin marks.

Clearly all these bikes are known to ride well enough to command a high price but they all look sloppier than the show bike links for sure.

Maybe because they are older frames?

It is nice to see the variations in joining tubes, internal cabling (Focus Izalco), and how big the metal inserts are.

I don't know if people can sense the difference in ride quality based on interior finish but I think smoother finishing might mean lighter weight.

The old size 58 Cannondale Six is stated to be 1288g (is the fork is part of this weight?). Look how sloppy it is, there's lots of extra resin built up in waves.

The latest Supersix Evo HiMod is so much lighter than this.

I wonder how much weight is saved by having less resin, or adding nanotube resin, or using newer carbon weaves?

If these are what brand name frames look inside; do those Chinese knock offs really look more like the disaster of a photo in the first post?

-

boolinwall

- Posts: 195

- Joined: Thu Aug 23, 2012 11:19 pm

Time actually uses a wax internal mold and puts the fibre on dry in a 360 degree weave around the mold. No sheets with seams. Then the resin is injected between the wax mold and the external mold to create the structure. It really is one of the most cutting edge ways to produce carbon fibre. Once the frame is cured, the wax is melted out, leaving a beautiful inside. It's a lot like investment casting in metal. BMC has adopted a very similar method with the Impec. Colnago uses polystyrene on their upper end bikes. Same idea, it expends when heated, thus pressuring the mold cavity. Some companies use air bladders, while others use oil bladders. The air bladders generally get tossed after each use, whereas the oil ones are usually thicker latex and are reusable. Think of it as using pneumatics or hydraulics to get a job done. Both are good, but one is clearly better than the other.

Just saw that topic, I have quite a few photos that I could share with you, I only have to found them...here is one of them (Specialized SL2) inside the downtube to the BB:

Otherwise, interesting topic

Otherwise, interesting topic

-

DrGalactus

- Posts: 96

- Joined: Fri Jun 01, 2012 11:45 am

- Location: Bristol, UK

- Contact:

Visit starbike.com Online Retailer for HighEnd cycling components

Great Prices ✓ Broad Selection ✓ Worldwide Delivery ✓

www.starbike.com

-

Johnny Rad

- Posts: 2026

- Joined: Fri Feb 17, 2006 6:22 am

- Location: Zion

From the inside of a Scott Addict head tube with their IMP single layup method / no lugs / no bonded tubes ... this was a shop demo piece, I believe.