Ok, brake calipers all cleaned up and installed. So, let's get on with the cabling. I cannot stress how important a good cable job is for both the aesthetics of the finished build, and even more importantly, the performance. I still would not trade a perfectly tuned mechanical system for an electric system. But it's got to be well set up for that statement to hold true, and in fairness it's a lot easier to get an electric system running perfectly as it was designed to do than it is to get the mechanical system to do so. What can also be a factor in the mechanical system is the size of the bike. A super small frame with a slammed stem for example, can make cable runs a little short with tight bends, and that can compromise shifting a bit, making proper attention to initial setup even more critical. Internally routed cables, while a non issue for an electric system, can be a pain in the ass for a mechanical system with its bends etc., again compromising perfect shifting. However, if you take the time to select components (bars, frame, etc), that adequately lend themselves to a nice mechanical setup, I don't think there's a better feeling on a fine road bike. I can throw around gears any which way, 1, 2, 3, or more cogs with the same motion instantly, as fast as my brain thinks about it, and also be throwing the chain around the front rings simultaneously during any of those motions. I just like the "feel" of mechanical. Like Cancellara was quoted as saying ... "I like to feel the wires..." . It's not "perfect", but because of that it allows you to manage your shifts, or finesse them if you will. Like a fine espresso where the end result is not just from pushing a button but more a result of the barista adjusting the grind, tamp, and dose of the coffee to match the environmental conditions and humidity at the time to extract that perfect shot. Ha, I am a Barista on a bike. Lol. Ok... enough pontificating... electric shifting is all well and good.... and I could have just as easily chose it for this build. But I didn't, and that's a personal decision based on what I like to experience while riding a bike. Plus, if all the bikes in my garage were currently electric... my entire garage floor would need to be a charging mat and all the bikes would need wireless charging capabilities otherwise it would be a nightmare to keep track of what was ready to ride and what needed charging. For now I'll leave the electric outlets for lights and stuff thankyou. Nuff said.

Ok... onto the matter at hand....

Let's get the stem and bars on... notice that the actual steer tube goes right to the top of the stem, normally I would cut it just above the stem to leave a lip. But in this case, the compression plug has a lip that sits on top of the steer tube, ensuring it doesn't fall down so far that it's not doing its job. So, I accounted for that and use the lip on the compression plug as my "1mm beyond the stem height) guideline. For a different brand of steertube where the compression plug fits completely inside the steertube, I would have cut the steertube 1mm longer than you see here, to end up with the same lip above the stem. It's that lip that provides a base for a 5mm spacer between the stem and the top cap and keeps it centered so that it doesn't move around on you. Cuz that ends up just looking dumb... oh, and I do use carbon paste between the steer tube and stem contact surfaces...

In this case, you can see how the expansion plug provides good support right from the top of the stem and, because of its length (who said size doesn't matter), extends all the way down just past the top headset bearing. It's solid. More than most. I'm not a fan of super lightweight parts where their purpose is holding strength or support, and that includes expansion plugs, skewers, and seatpost clamps. Some are better than others for sure, but some... I just would rather avoid completely for the hassles they "may" cause. I'm not 140lbs either, so I always like to err on the stronger side of things when it comes to my bike stuff. So on the top of the stem goes the 5mm spacer and the top cap and there is plenty of space between the bottom of the top cap and the top of the compression plug to ensure that it doesn't bottom out when applying the preload.

And finally... icing on the cake....

Yes, I know I've shown it before, but I'm pretty proud of it

.

So, cable housing length. You want it not too long, not too short, you want it just right... so that they have relaxed bends, and as few as possible. Straight lines are better than curves, etc. etc. In a lot of frames these days, where the derailleur cables get routed through the downtube, it can be best to do the crossover within the downtube routing, and that's what all my internally routed bikes have now. It just makes for a nice smooth bend in the derailleur cables from the bar to the downtube. You just have to make sure there is enough length to allow the bars to be completely turned till they touch the top tube without being restricted by cables that are too short. I'll start with the derailleur cables. I run one from the lever to the cable stop in the opposite side of the downtube, temporarily taping it along the bars along it's natural run. I mark it. I take it off and cut it, then I cut the other side derailleur housing the exact same length. If they are the same length and the levers are in the same spot on each side of the bar, then you can be assured that they will cross each other in the center front of the bike, which looks nice.

In this case, I even went so far as to cut the cables so that the "Campagnolo" logos on the cable housing would end up in the same spot on each side of the bike just up from the cable stops in the down tube. That meant a couple more cuts than usual. On a new build, I like to mark it, then cut and finish the housings off the bike... to ensure the same exact length and, for the brake housings, to be able to finish up the ends on a bench grinder. A hand file will work as well, just takes longer.

So, let's assume the derailleur cable housings have been cut as they're the easiest to get right. I just cut them square and make sure they are "unsquashed" at the ends. I'll stick an awl in the ends to make sure it's good. And when you install the ends in the levers themselves, make sure that they are inserted fully into their seats.

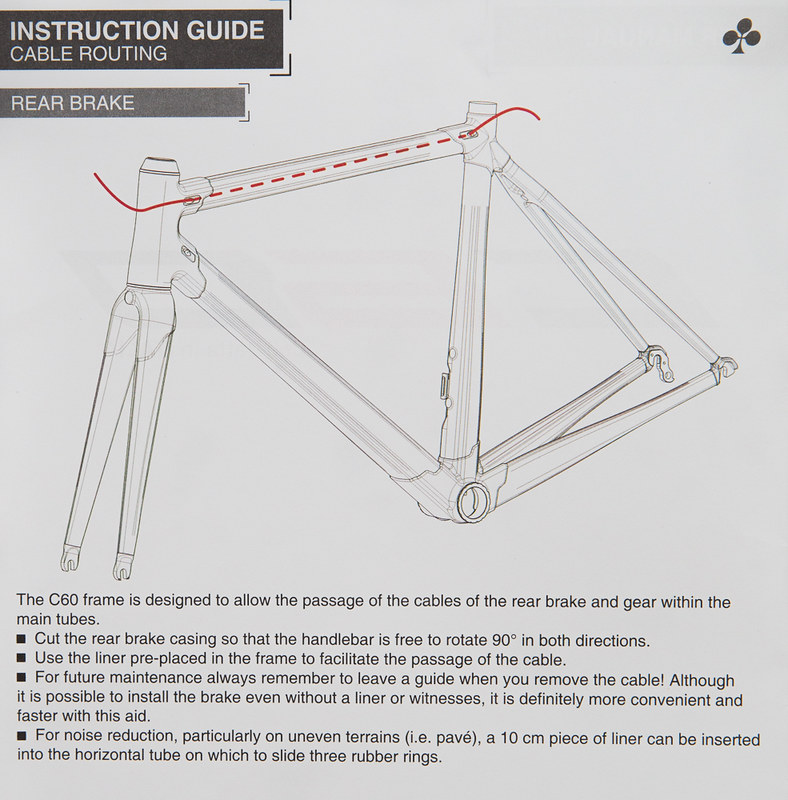

The brake housings are a little more work. I'll always attempt to get all the cables to cross in front of the bike under the stem at exactly the same spot if possible. First I mount the derailleur cable housings and route them into their stops. They will cross in the center by default since they are the same length. All good so far. Then to determine the brake housing length, a little more trial and error is involved. I mount the front wheel and front brake because I want to mark the housing where it will actually end up being upon final setup and adjustment. I want a clean straight line up from the front brake caliper and nicely curving into the bar hopefully crossing at the same place the derailleur cables are crossing. Same with the rear brake housing. Run it from the lever and mark it at the rear brake stop on the top tube so that it curves nicely, crossing in the same place out front and entering the cable stop fairly straight but with enough slack so as not to get stretched when you turn the handlebars all the way to the right to the extreme of touching the top tube.

Here's the look I'm going for, from the front view... I got lucky here and all cable housings cross within about a 5mm circle out front and directly underneath the stem... also, keep in mind where the finishing tape will ultimately end and temporarily tape the housings at that point to know how it will look at the end... also, with this type of crossing in the downtube routing the cable housings don't ever come close to touching the headtube. In fact, there isn't a single point on the entire frame where a derailleur housing or a brake housing comes into contact with the frame itself other than at the exact point of the cable stop.

Before I forget, note the absence of the inline cable adjuster for the front derailleur in the pic above. I'll talk more about that when I get to tuning the drive train, but suffice to say for now I think the adjusters are hideous and I've figured out how to dial in the front derailleur without it, but admit that you should probably have it installed unless you're very patient about learning how to dial in the front shifting without it.

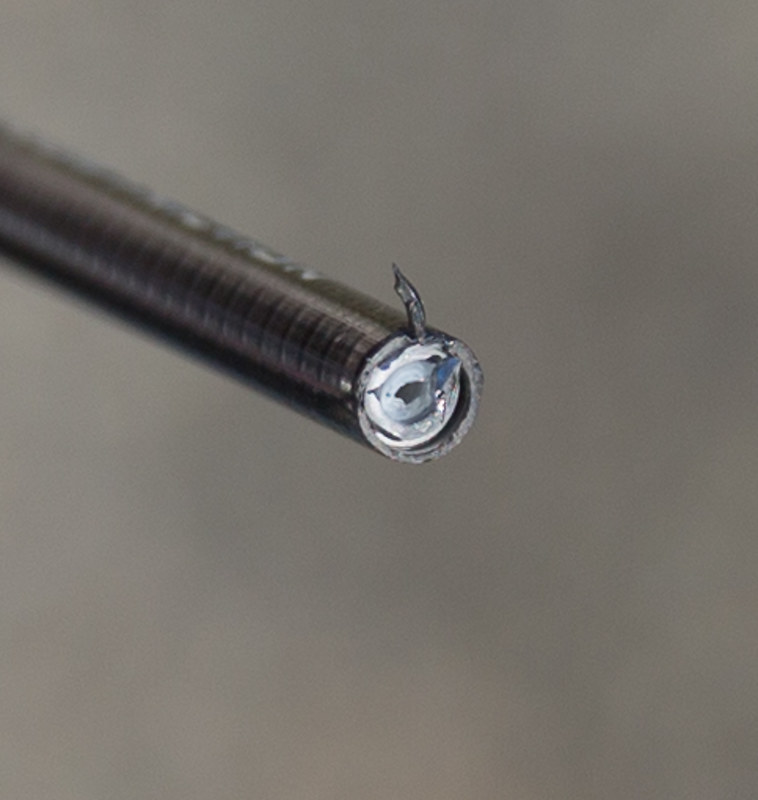

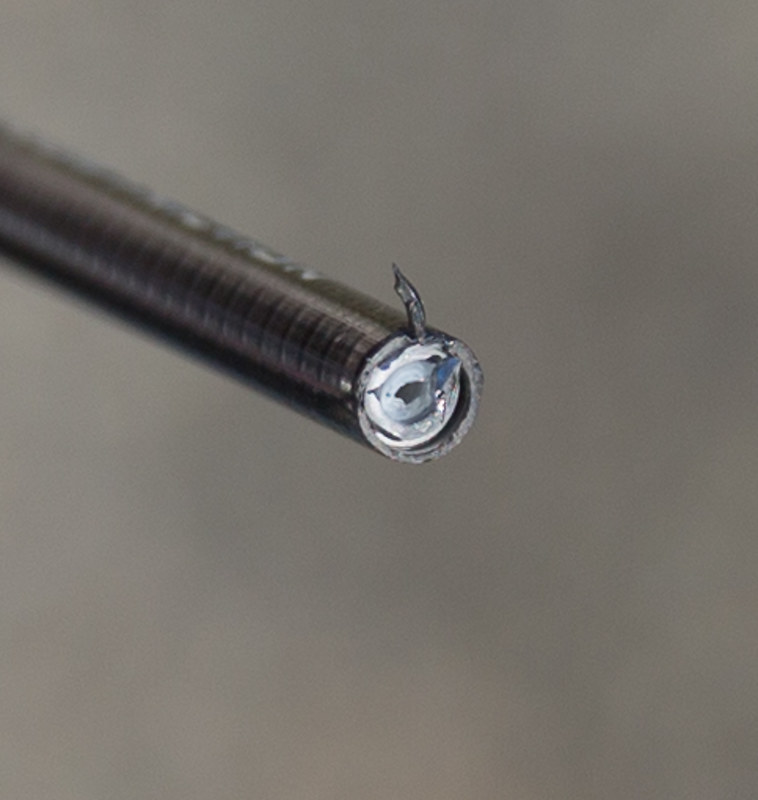

Ok... upon cutting the brake housing, the ends are raw, rough and not very "finished", with sharp bent burrs that left untouched will cause very rough operation of the brake cable... the end of this cut in the pic is actually not bad compared to most, but still needs the same work as a terrible cut would...

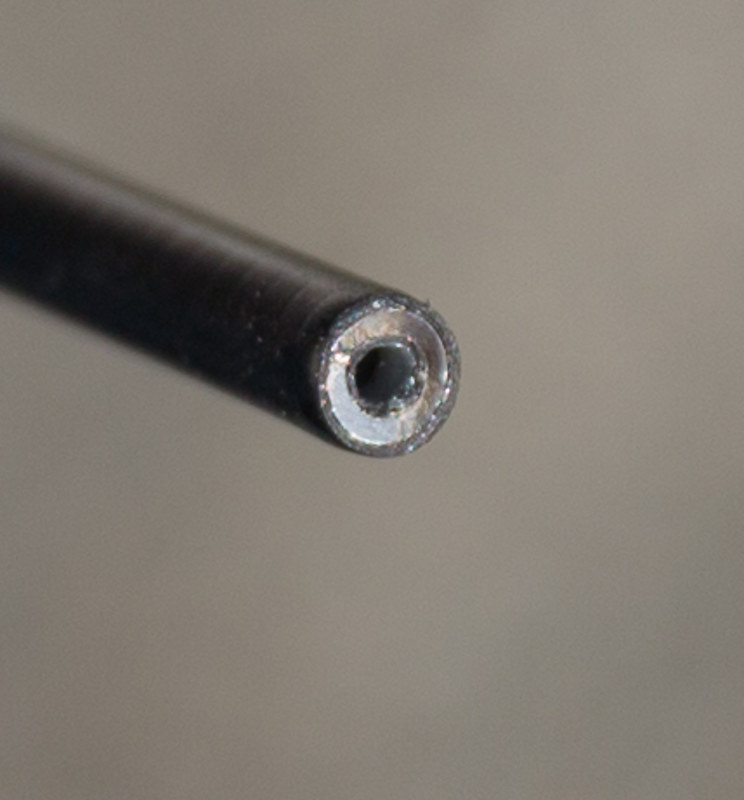

And off to the grinder we go... with caution. If you just hit it with the grinder in one fell swoop it will get too hot and melt the liner into itself. Not good. So, I like to just basically sweep the end quickly across the grinder wheel while simultaneously turning it in my hands, then quickly poke the end with a little awl to make sure nothing is melting. Give it a few seconds to cool then repeat until you have a perfectly square and round opening that does not constrict the actual brake cable in any way. I use a spare length of brake cable to make sure this is the case.

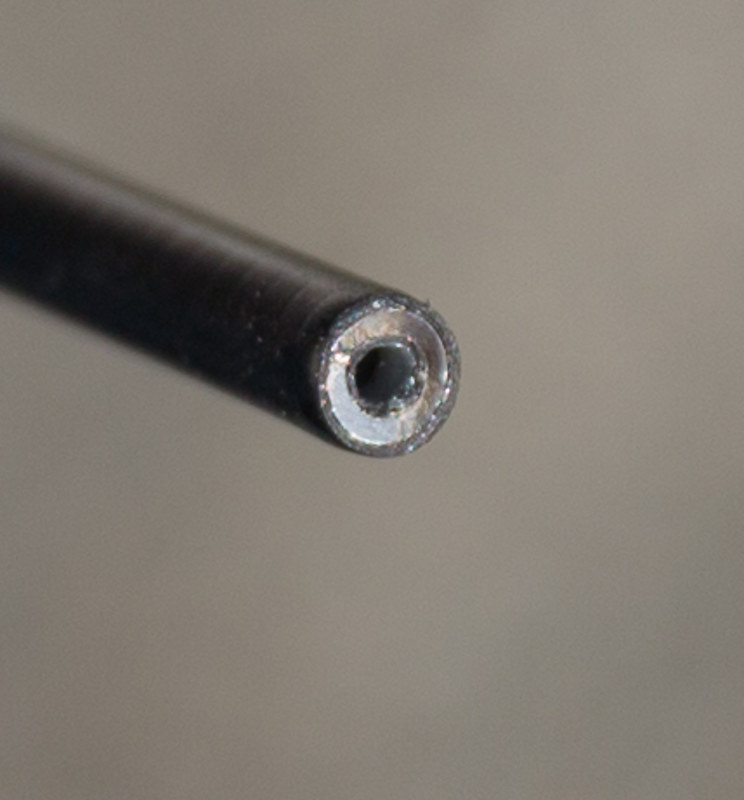

Here's what I want to end up with...

I fashioned a makeshift tool out of cut off piece of 1.5/1.7mm diameter Wheelsmith spoke, and ground the end into a point. I make sure everything is clear just by sticking the spoke in the housing and working it a bit. A Campy steel brake cable is 1.6mm, so this spoke is the perfect tool for this...

Ok, so now I actually run the cables from the levers to their respective places. But first I just run a light coating of Shimano's Cable lube over the lengths of cable that will actually be inside the housing...

Next, I run the derailleur cables down through the downtube and out the slot at the bottom bracket, making sure they cross once but are not twisted. Keep them separated so you know which is which once they are both out of the slot...

Then I take my BB cable guide "assembly" and run the cables through the tubing then insert everything back up there and lock it down with the cable guide screw (using a dab of low strength Loctite 222 on the screw). Since I want a length of tubing inserted back up the tube I have to run the cables through before setting the cable guide in place, so that in the end it looks like this....

It really makes for a nice "sealed" system in that crud from the road doesn't gunk it up, although that never seems to be a problem. What can be much more a problem is sports drink that finds it way down there. I've seen that area so gunked up with sports drink that the owner thought the front shifter was broken. So did I when I first activated the shifter to see what was going on, but as soon as I turned the bike over it was clear what the issue was. Just cleaned it up and the shifter was fine. I only use plain water in my bottles so have never experience that, but it's still nice to know things are staying clean down there.

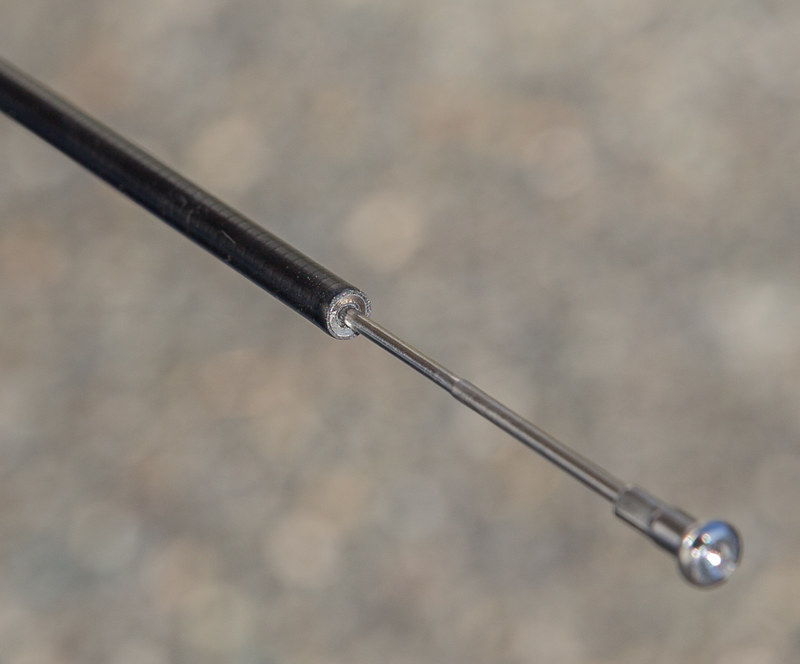

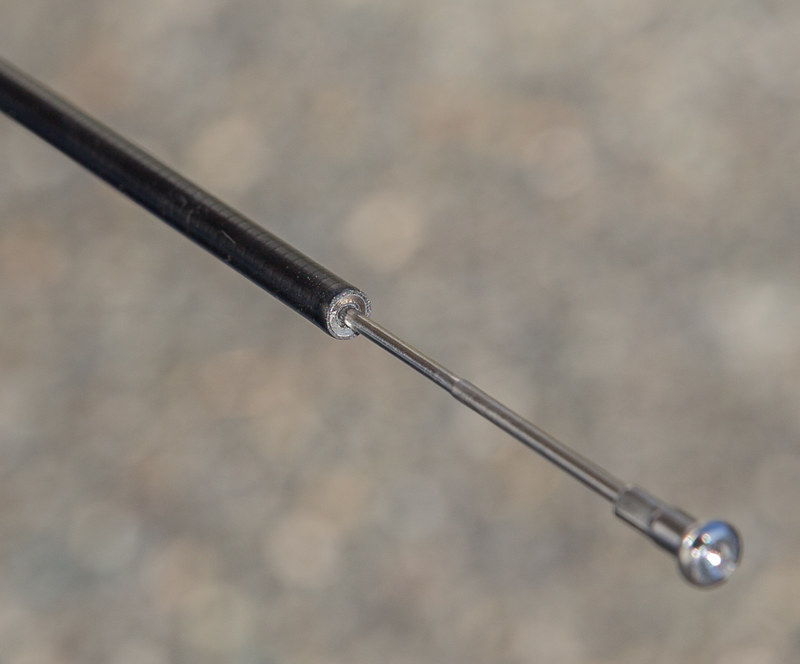

Here's a pic of the front derailleur cable and tubing coming up from the BB on it's way to the front derailleur. Note how thick walled this PTFE tubing is. And it's inner diameter is large enough for a derailleur cable but not large enough for a brake cable. The derailleur cables slide through this stuff like butter...

And finally, I add a little grub seal like Campy supplies for the rear derailleur cable (If I can find one), on the end of the tubing to really seal it up but without adding any friction. These grub seals are super flexible...

Ok... that's it for the derailleur cables. The rear brake cable run proved, shall we say, "interesting". I'll deal with that in the next post.