Craddock

Moderators: MrCurrieinahurry, maxim809, Moderator Team

-

whilgenberg

- Posts: 57

- Joined: Wed Aug 08, 2012 5:54 pm

Out of curiosity how difficult was it to mitre the tubes with Dyneema? Given that Kevlar is a real joy to cut, I can't imagine Dyneema would be much better. Sort of akin to Innegra.

Visit starbike.com Online Retailer for HighEnd cycling components

Great Prices ✓ Broad Selection ✓ Worldwide Delivery ✓

www.starbike.com

whilgenberg wrote:Out of curiosity how difficult was it to mitre the tubes with Dyneema? Given that Kevlar is a real joy to cut, I can't imagine Dyneema would be much better. Sort of akin to Innegra.

It's a very interesting material and you're right to think about the difficulties of cutting. It requires some different techniques in fabrication. New sharp kevlar shears were a good help.

It's fillet Friday so here's a view of the current frame with completed fillets. These shapes provide smooth transitions between the tubes for the UD fibres to lay on.

Plenty of work has gone in so far and the frame is now ready for the wraps.

This one has a BSA threaded BB and internal cable routing through the top tube. Left hand rear brake for the keen eyed.

IMG_4299 by Filament, on Flickr

IMG_4299 by Filament, on Flickr

Plenty of work has gone in so far and the frame is now ready for the wraps.

This one has a BSA threaded BB and internal cable routing through the top tube. Left hand rear brake for the keen eyed.

IMG_4299 by Filament, on Flickr

IMG_4299 by Filament, on Flickr@Craddock, I love "Fillet Fridays", and think it'd be great if you could maybe add just a short one liner sentence or explanation as a caption to some of your pics that explain what's going on to those of us that find it highly interesting but think, "what is that doing?" Specifically I'm thinking about the shots "from your workshop this week" post.

Of course, the paint ball scheme is self explanatory... you were high that day. Lol

Of course, the paint ball scheme is self explanatory... you were high that day. Lol

Colnago C64 - The Naked Build; Colnago C60 - PR99; Trek Koppenberg - Where Emonda and Domane Meet;

Unlinked Builds (searchable): Colnago C59 - 5 Years Later; Trek Emonda SL Campagnolo SR; Special Colnago EPQ

Unlinked Builds (searchable): Colnago C59 - 5 Years Later; Trek Emonda SL Campagnolo SR; Special Colnago EPQ

Calnago wrote:@Craddock, I love "Fillet Fridays", and think it'd be great if you could maybe add just a short one liner sentence or explanation as a caption to some of your pics that explain what's going on to those of us that find it highly interesting but think, "what is that doing?" Specifically I'm thinking about the shots "from your workshop this week" post.

Of course, the paint ball scheme is self explanatory... you were high that day. Lol

Missed this, let's try and shed a little light on the process.

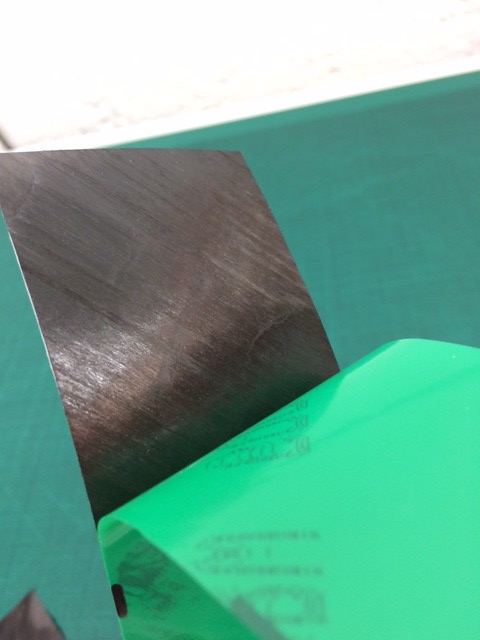

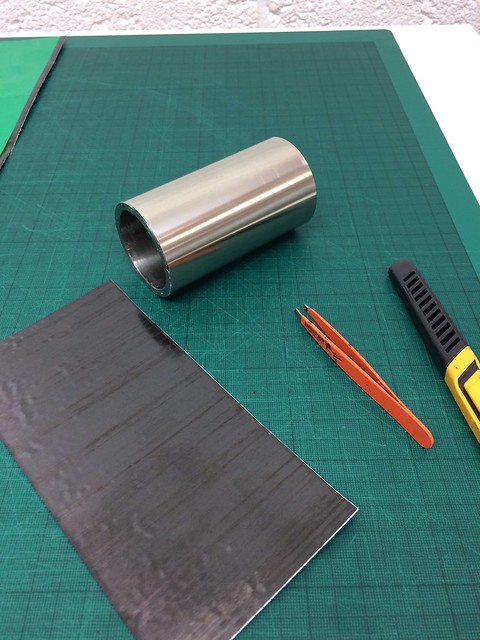

Here we have a small piece of prepreg carbon. It has B stage epoxy already applied in just the right amount and it's a little tacky at room temperature. The carbon is unidirectional. This is what I use to wrap the tube junctions.

IMG_4308 by Filament, on Flickr

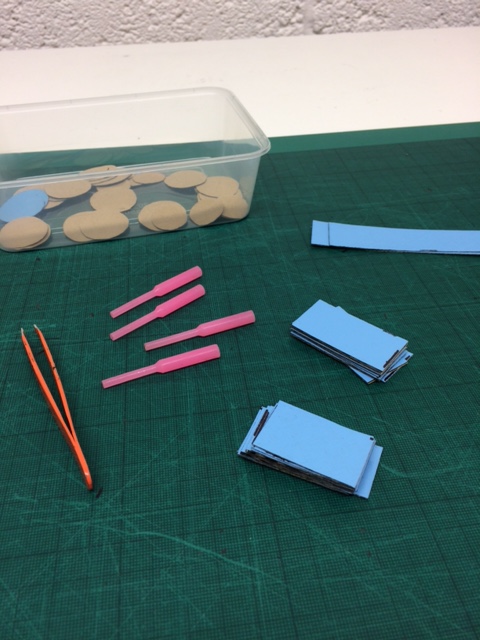

IMG_4308 by Filament, on FlickrNext we have some more pieces of prepreg that I use for making cable stops and bottle bosses. These are a 3K 2/2 twill weave carbon with a little more epoxy content. The pink silicone plugs form the holes in the cable stops.

IMG_4312 by Filament, on Flickr

IMG_4312 by Filament, on FlickrHere is the range of vacuum bagging materials which are used to make a multi-layer sealed envelope for compaction of the laminate. There is release film, peel ply (only used in some cases), breather, bagging film and sealant tape.

IMG_4314 by Filament, on Flickr

IMG_4314 by Filament, on FlickrThis gauge measures the vacuum level inside the bag and reads down to minus one atmosphere. I test the integrity of the bag seal by performing a drop test which is simply disconnecting the pump line and monitoring the needle. If the level holds then the seal is good and it can go in the oven to cure. The outside air pressure pushes the bag materials against the laminate with a uniform 1 bar.

IMG_4318 by Filament, on Flickr

IMG_4318 by Filament, on FlickrA cured head tube joint. The green tape is flash breaker.

IMG_4325 by Filament, on Flickr

IMG_4325 by Filament, on FlickrCheers!

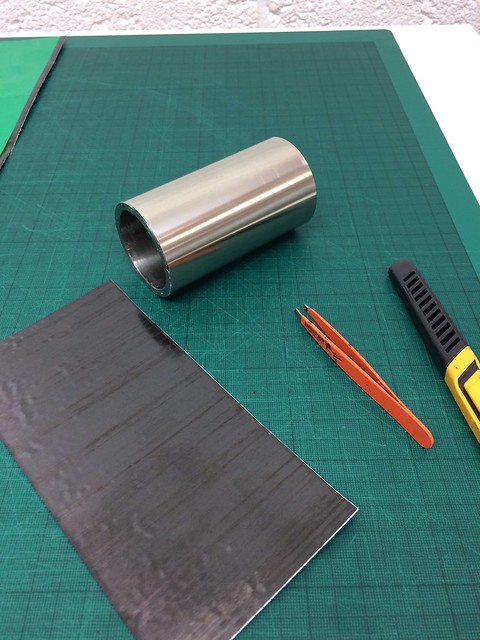

I've been making a carbon BB shell for a tandem eccentric BB. The mandrel is stainless steel and gives the finished shell a nice smooth interior.

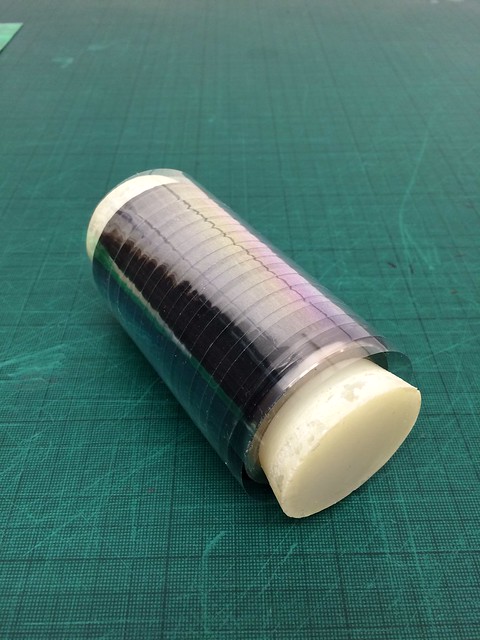

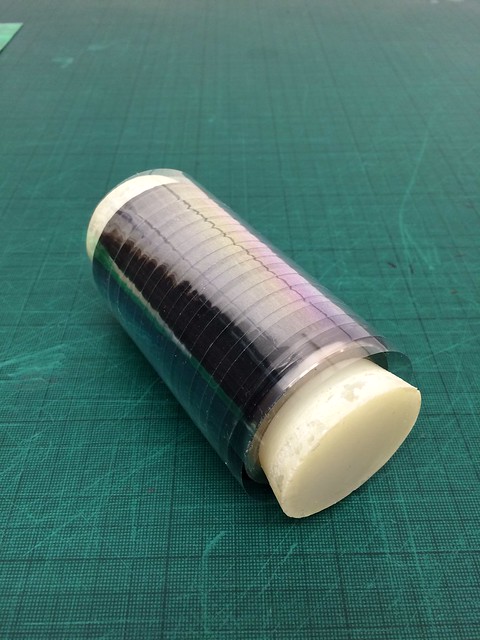

The carbon plies are wrapped over the mandrel and then clear shrink tape is wrapped over the top. This tape shrinks in the heat of the oven to consolidate the laminate.

Making a BB shell by Filament, on Flickr

Making a BB shell by Filament, on Flickr

Wrapped BB shell by Filament, on Flickr

Wrapped BB shell by Filament, on Flickr

The carbon plies are wrapped over the mandrel and then clear shrink tape is wrapped over the top. This tape shrinks in the heat of the oven to consolidate the laminate.

Making a BB shell by Filament, on Flickr

Making a BB shell by Filament, on Flickr Wrapped BB shell by Filament, on Flickr

Wrapped BB shell by Filament, on Flickr@craddock - I can't remember if I asked this when you posted the TT tandem a while back, but is the Bushnell eccentric in direct contact with the carbon shell, i.e. you don't bond in an insert after the shell has cured right? Have you had any issues with it moving? Do you use a retaining compound? Also, it seems like your mandrel is nice and thick, is there a particular reason for using the plugs too?

The carbon is insulated against electron exchange. Carbon grip paste will help it to hold securely with a moderate torque on the bolts.

The tubes have been cut and bonded together so we now have the overall shape of the tandem frame. We've opted for no lateral tube this time and 724mm BB centres for a belt drive. The stoker's BB shell has a threaded titanium BSA insert. Disc brakes with through axle and an internally routed hose.

The transitions between the tubes are made with a blend of a structural epoxy adhesive. The smooth curves provide a nice surface on which to apply the carbon prepreg wraps. That's the next step.

Current weight is 2025g.

IMG_4413 by Filament, on Flickr

IMG_4413 by Filament, on Flickr

IMG_4418 by Filament, on Flickr

IMG_4418 by Filament, on Flickr

IMG_4417 by Filament, on Flickr

IMG_4417 by Filament, on Flickr

The transitions between the tubes are made with a blend of a structural epoxy adhesive. The smooth curves provide a nice surface on which to apply the carbon prepreg wraps. That's the next step.

Current weight is 2025g.

IMG_4413 by Filament, on Flickr

IMG_4413 by Filament, on Flickr IMG_4418 by Filament, on Flickr

IMG_4418 by Filament, on Flickr IMG_4417 by Filament, on Flickr

IMG_4417 by Filament, on Flickr

Visit starbike.com Online Retailer for HighEnd cycling components

Great Prices ✓ Broad Selection ✓ Worldwide Delivery ✓

www.starbike.com